- Apr 22, 2022

- Agescan International

- Tungsten

- 3 Comments

Only a small handful of highly dense metals are found in nature. Out of all elements, tungsten is the only one you can employ in most density-driven applications. Tungsten is tough and durable, so it is employed in so many applications.

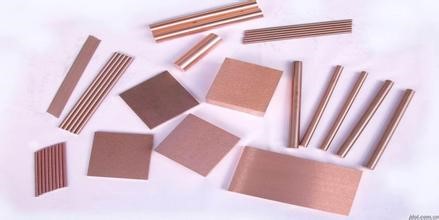

Alloy is a metal that combines two or more metal elements to improve strength or corrosion resistance. The tungsten alloy family has a wide range of industrial applications due to its power.

Here’s some more information about the tungsten alloy family and the most common types of tungsten alloys.

Tungsten nickel-iron alloys

In terms of flexibility, strength, and density, tungsten nickel-iron alloys are the most prevalent tungsten alloys. Tensile strengths of these metals range from 600 to 1000 MPa, much exceeding those of most, if not all, other alloys.

These alloys offer good machining characteristics and plasticity and the ability to endure high temperatures while still having a thermal conductivity five times that of die and punch steels. They can shield 1.7 times more radiation than lead and are non-toxic to biological systems.

These tungsten heavy alloys are magnetic due to iron, which is vital to know if they can be used in magnetism-sensitive processes such as medical imaging equipment. Tungsten nickel-iron alloys have a low expansion coefficient, making them ideal for glass-to-metal seals, and they have high moduli of elasticity, making them resistant to elongation.

These alloys are suitable for radiation shielding because of their high density and radiation resistance, making them ideal for protective components. Balance weights, security and military applications, ballasts, bearing assemblies, and other uses are only a few examples.

Tungsten nickel-copper alloys

Tungsten nickel-copper alloys are the non-magnetic brothers of tungsten nickel-iron alloys. They’re equivalent to nickel-iron alloys in popularity, albeit with lower tensile strength (500-700 MPa) and flexibility. Despite their high mechanical strength, they are excellent electrical conductors and simple to make.

Tungsten nickel-copper alloys are the non-magnetic brothers of tungsten nickel-iron alloys. They’re equivalent to nickel-iron alloys in popularity, albeit with lower tensile strength (500-700 MPa) and flexibility. Despite their high mechanical strength, they are excellent electrical conductors and simple to make.

In terms of thermal stability and radiation resistance, they are comparable to other tungsten alloys. Tungsten nickel-copper alloys are non-magnetic means that you can utilize in situations where tungsten nickel-iron alloys would be magnetically disruptive.

Oncology equipment, electrical sensor shields, guidance system components, and military technology all use them. Because of its significant density and strength, you can utilize heavy tungsten alloy as kinetic energy tungsten alloy penetrators and other ordnance.

Tungsten carbide

Tungsten carbide is a ceramic-like compound created through the sintering process, in which carbon black is mixed with tungsten powder and cooled to form a rigid and brittle cement.

It can be mono tungsten carbides (WC) or a matrix of ditungsten carbides (W2C), and each has its unique set of properties based on the composition and fabrication method.

It is the most common tungsten compound, accounting for 60% of all tungsten applications, and comes in over 5000 grades and designations. Today, it is one of our most potent engineering materials, with rigidity and density 2-3 times that of ordinary steel.

While tungsten carbide is tough to manipulate, forge, machine, turn, or deform once created, it is resistant to galling, scratches, erosion, corrosion, and extreme temperature changes.

It can last up to 100 times longer than steel and has a hardness comparable to diamond. Tungsten carbide tools can easily cut almost any other material and be utilized at high speeds due to their hardness.

Cutting tools, ammunition, mining and drilling, nuclear, recreational sports, medical equipment, jewelry, and other applications are just a few of tungsten carbide’s many applications.

Conclusion

We appreciate you taking the time to read our blog and hope you found it informative. Explore our website to learn more about the different varieties of tungsten alloys and other refractory metals. Agescan International is a leading supplier of specialty materials, feel free to contact us for any queries.

Pingback: Which Are Common Types Of Tungsten Heavy Alloys...

Pingback: canadianpharmaceuticalsonline.home.blog

Pingback: My Homepage