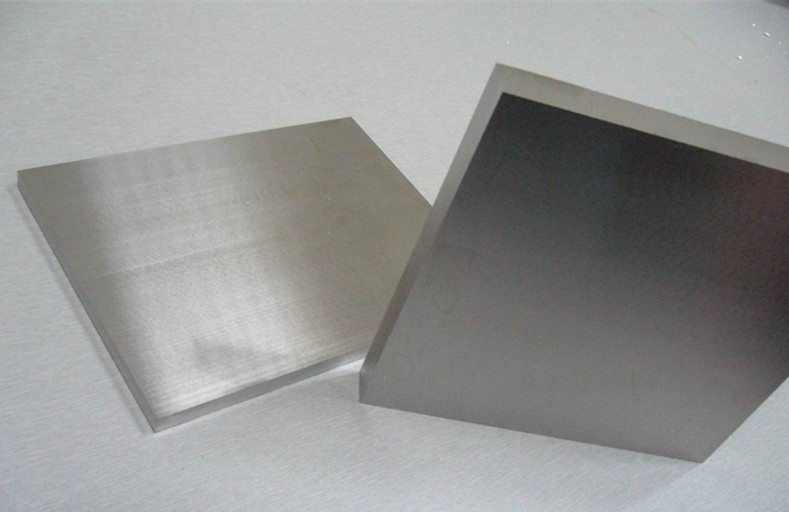

Description

Tungsten alloy plates are refractory metal, which have two-phase composites consisting of W-Ni- Fe or W-Ni- Cu or even W-Ni-Cu-Fe, some tungsten alloys also contain Co、Mo、Cr, etc. Tungsten alloy can be machined into various shapes, such as rods, cubes, blocks, bricks, rings, plates, etc.

Applications for Tungsten Alloy Plates:

1) Sports goods: Professional tungsten alloy plates can be used for dart benchmarking, and fishing sinkers including bullet types, water drop types, pipe types etc.

2) Counterweights: high-density tungsten alloy plates are used as counterweights in various fields, such as counterweights for mechanical hammers; fly hammers; oil drilling platforms; dart rods, car counterweight pieces, etc.

3) Electrode material: it can be made into electrodes, welding rods, electrical contacts and pneumatic breakers.

4) Electronic sealing pieces: due to its favorable high temperature resistance and thermal properties, the electronic industry has started to adopt tungsten alloy plates as electronic sealing pieces, electrical discharge machining of electrode and resistance welding electrodes; high proportion electrical contacts, and air circuit breakers in the contacts.

5) It can be machined into X-ray target material, collimators, nuclear containers, syringe shielding etc.

Introduction of Tungsten Alloy Plate

- Width*Length: (2.0-250.0 mm) * (2.0-250.0mm)

- Thickness: 2mm-15mm

- Density: 15.8-18.75 g/cm3

- Composition: W content: 85-99%, W-Ni-Fe, W-Ni-Cu

- Surface: Sintering surface, Forged surface, Ground surface

Tungsten alloy plates are produced by good processing property billets and special cold and hot rolling technology; they can be used to make tungsten targets, tungsten heat elements, tungsten radiation shields and tungsten channels for electronics, lightening, and electro-vacuum industries.

Tungsten alloy plates play a very important role in manufacturing of collimators for nuclear medicine, nuclear research, geological prospecting and security inspection. These materials provide reliable protection against X-rays and gamma radiation.

The thickness of the tungsten alloy plate is as follows:

- Foil – a thickness of less than 0.005 in. (0.13 mm).

- Plate – thickness greater than or equal to 0.188 inches (4.75 mm).

- Sheet – thickness less than or equal to 0.187 inches (4.75 mm) or greater than or equal to 0.005 inches (0.13 mm)