- Mar 14, 2022

- Agescan International

- Radiation Shielding

- 0 Comments

We are specialists in the customization of tungsten heavy-alloys for Nuclear Energy, Nuclear Medicine/Radioisotope, symptomatic imaging and non-destructive testing businesses. Minimum radiation exposure is accomplished by utilizing materials that expand safeguarding. The denser the material, the more significant level of protection it gives. With a thickness roughly 1.7 times higher than lead, Tungsten Heavy Alloy shielding ensures radiation openness is kept to a base. It is a practical choice for some applications where lead isn’t possible and is solid and exceptionally adaptable into precision parts.

Tungsten Radiation Shielding has a thickness of up to 18.89 g/cm3 versus lead at 11.34 g/cm3. Its simplicity of mechanical handling/machining, high malleability and strength make it a reasonable choice for some applications where lead isn’t plausible whether it be for size decrease, amplifying weight in huge or little depressions or for radiation safeguarding. Tungsten Radiation Shielding is solid and profoundly adjustable.

Why Tungsten Shielding?

Tungsten has a thickness that is roughly 1.7 times higher than lead, accordingly, it gives a more significant level of shielding. It is a reasonable choice for applications where lead is certainly not a plausible choice, including for size minimization, and expanding weight in huge or little cavities for radiation safeguarding. It is solid and profoundly adaptable to precision components.

Tungsten is the favored decision for clinical and modern settings that require radiation shielding since it utilizes less material than lead to give a similar degree of retention. Great material for safeguarding, tungsten ensures minimum radiation exposure and guarantees ALARA objectives in the work environment. Machinability, radiographic thickness, strength, low poisonousness, and heat resistance, take into account predominant design flexibility versus other shielding materials.

Use of Tungsten heavy alloys

- ATOMIC FUEL AND WASTE ASSAY

Spent atomic fuel (SNF) and waste materials are exposed to analytical methodology to decide their radionuclide content. In fuel test and waste assay frameworks, where levels of radioactivity are estimated, there is a requirement for precise collimators to concentrate the approaching radiation.

Our tungsten compound can be machined to exceptionally close resistances to create the necessary collimators and meet client demands. Thus, the role of tungsten in nuclear shielding is unmatched by other materials

We provide high thickness and predominant weakening qualities taking into consideration more modest, more minimal compelling shielding to be set around scanners, fulfilling complex design prerequisites with no compromise with the wellbeing or effective activity.

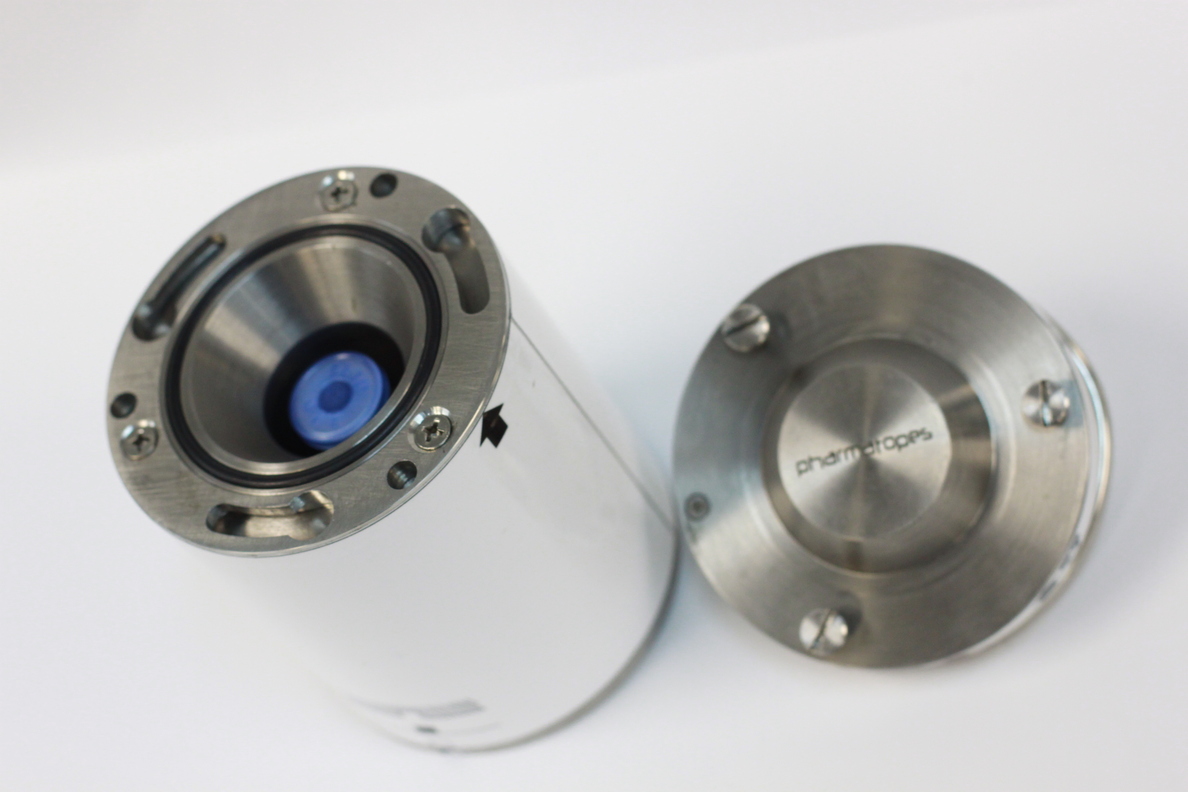

- BUNDLING FOR RADIOACTIVE MATERIALS

In circumstances where space is of specific concern and reduced bundling compartments are an unquestionable requirement, the high thickness of our tungsten heavy alloys implies that a fundamentally more modest container can be utilized with no compromise about compelling protection.

- ESTIMATION AND INSPECTION INSTRUMENTS

Our tungsten composite is the ideal answer for originators searching for safeguarding materials for use in little spaces, for example, around pipelines where gas or fluid through-stream should be checked. As it is 60% thicker than lead, the tungsten composite can be utilized to make more solid parts that fit effectively into limited spaces without compromising shielding policies.

- RADIATION TOLERANT CAMERAS

Where CCTV cameras are utilized in hot cells and other antagonistic conditions, safeguarding the central processor that cycles the computerized pictures is basic. Utilizing our tungsten combination, for this reason, guarantees solid demonstrative pictures are created, keeping up with plant effectiveness.

Lead vs. Tungsten for Radiation Shielding

There are a few distinctions between lead and tungsten. Choosing the right radiation protecting choice relies upon the prerequisites of the venture.

- Lead is more affordable than Tungsten.

- Lead is more powerless in light of the fact that it is delicate.

- To forestall openness, a lead should be exemplified or covered.

- Less tungsten is expected to give a specific constriction.

From idea to completed product, we are the forerunner in the assembling and supply of radiation protection products and materials in North America. You can find additional data from our site or you can contact us straightforwardly, and we will assist you with selecting the most suitable radiation protecting solution for your company.

The role of tungsten in nuclear shielding is next to none. While lead has been the traditional choice of material for years, companies are replacing it with tungsten to achieve effective benefits.

For more information feel free to contact us.